to select

to navigate

esc to close

Go Back

Custom Packaging

Bags & Liners

Tubing & Film

Packaging Supplies

Shop by Application

Hi there,

how can we help you today?

Shipping options will change based on location.

Current ZIP Code:

Update zip code

User my current location

Order before 4pm EST for same-day shipping on in-stock items!

Lowest Price Guarantee

30-Day Returns & Exchanges

100% Satisfaction Guarantee

Specials

Box Type

Width

Length

Height

Quantity

Filter this list

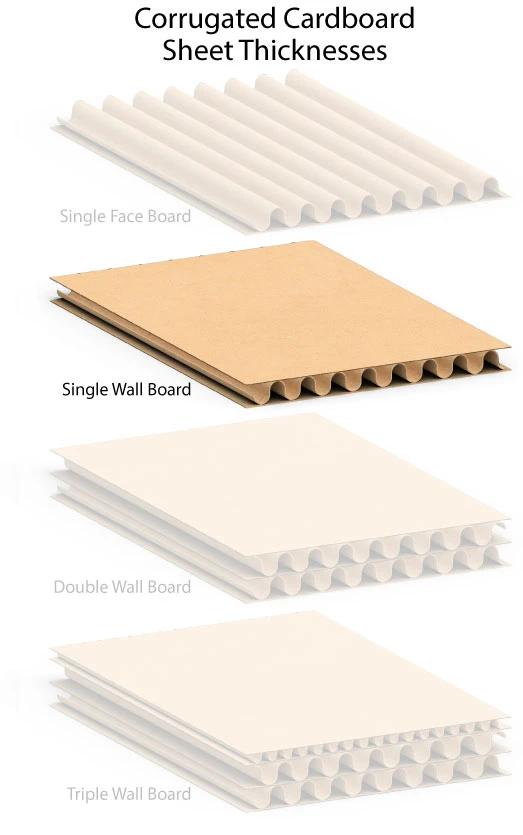

Standard corrugated boxes are commonly used for shipping and storing products. These boxes are made of corrugated fiberboard, which consists of three layers of paper: an inner liner, an outer liner, and a corrugated medium that is sandwiched between the two liners.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 4" | 4" | 6" | Standard | 25 / Bundle |

As low as $17.30 |

|

| 5" | 5" | 3" | Standard | 25 / Bundle |

As low as $19.25 |

|

| 5" | 5" | 8" | Standard | 25 / Bundle |

As low as $23.70 |

|

| 6" | 4" | 4" | Standard | 25 / Bundle |

As low as $15.10 |

|

| 6" | 6" | 4" | Standard | 25 / Bundle |

As low as $15.40 |

|

| 6" | 6" | 5" | Standard | 25 / Bundle |

As low as $16.60 |

|

| 7" | 5" | 3" | Standard | 25 / Bundle |

As low as $18.85 |

|

| 7" | 5" | 5" | Standard | 25 / Bundle |

As low as $15.50 |

|

| 7" | 6" | 4" | Standard | 25 / Bundle |

As low as $20.20 |

|

| 7" | 7" | 4" | Standard | 25 / Bundle |

As low as $18.70 |

|

| 7" | 7" | 4 1/2" | Standard | 25 / Bundle |

As low as $18.45 |

|

| 7" | 7" | 5" | Standard | 25 / Bundle |

As low as $19.00 |

|

| 7" | 7" | 6" | Standard | 25 / Bundle |

As low as $20.80 |

|

| 7" | 7" | 10" | Standard | 25 / Bundle |

As low as $25.55 |

|

| 8 3/4" | 4 3/8" | 9 1/2" | Standard | 25 / Bundle |

As low as $18.75 |

|

| 8" | 5" | 5" | Standard | 25 / Bundle |

As low as $16.25 |

|

| 8" | 6" | 3" | Standard | 25 / Bundle |

As low as $16.65 |

|

| 8" | 6" | 4" | Standard | 25 / Bundle |

As low as $16.70 |

|

| 8" | 6" | 6" | Standard | 25 / Bundle |

As low as $19.65 |

|

| 8" | 8" | 3" | Standard | 25 / Bundle |

As low as $23.60 |

|

| 8" | 8" | 5" | Standard | 25 / Bundle |

As low as $24.20 |

|

| 8" | 8" | 6" | Standard | 25 / Bundle |

As low as $21.45 |

|

| 9" | 4" | 4" | Standard | 25 / Bundle |

As low as $20.00 |

|

| 9" | 5" | 4" | Standard | 25 / Bundle |

As low as $16.35 |

|

| 9" | 5" | 5" | Standard | 25 / Bundle |

As low as $16.95 |

|

| 9" | 6" | 4" | Standard | 25 / Bundle |

As low as $17.65 |

|

| 9" | 6" | 5" | Standard | 25 / Bundle |

As low as $19.70 |

|

| 9" | 6" | 6" | Standard | 25 / Bundle |

As low as $21.10 |

|

| 9" | 7" | 5" | Standard | 25 / Bundle |

As low as $21.55 |

|

| 9" | 7" | 7" | Standard | 25 / Bundle |

As low as $23.70 |

|

| 9" | 8" | 6" | Standard | 25 / Bundle |

As low as $25.95 |

|

| 9" | 8" | 8" | Standard | 25 / Bundle |

As low as $25.35 |

|

| 9" | 9" | 7" | Standard | 25 / Bundle |

As low as $25.50 |

|

| 10" | 5" | 4" | Standard | 25 / Bundle |

As low as $21.65 |

|

| 10" | 6" | 3" | Standard | 25 / Bundle |

As low as $22.70 |

|

| 10" | 7" | 5" | Standard | 25 / Bundle |

As low as $22.15 |

|

| 10" | 7" | 7" | Standard | 25 / Bundle |

As low as $24.65 |

|

| 10" | 8" | 5" | Standard | 25 / Bundle |

As low as $24.45 |

|

| 10" | 8" | 6" | Standard | 25 / Bundle |

As low as $23.10 |

|

| 10" | 8" | 12" | Standard | 25 / Bundle |

As low as $29.90 |

|

| 10" | 10" | 6" | Standard | 25 / Bundle |

As low as $24.45 |

|

| 10" | 10" | 8" | Standard | 25 / Bundle |

As low as $29.80 |

|

| 11" | 8" | 6" | Standard | 25 / Bundle |

As low as $24.00 |

|

| 11" | 8" | 8" | Standard | 25 / Bundle |

As low as $28.65 |

|

| 11 1/4" | 8 3/4" | 9 1/2" | Standard | 25 / Bundle |

As low as $30.00 |

|

| 11 1/4" | 8 5/8" | 10" | Standard | 25 / Bundle |

As low as $26.45 |

|

| 11 1/4" | 8 3/4" | 12" | Standard | 25 / Bundle |

As low as $31.40 |

|

| 11" | 11" | 9" | Standard | 25 / Bundle |

As low as $35.40 |

|

| 12" | 5" | 4" | Standard | 25 / Bundle |

As low as $18.80 |

|

| 12" | 5" | 5" | Standard | 25 / Bundle |

As low as $20.15 |

|

| 12" | 6" | 3" | Standard | 25 / Bundle |

As low as $20.10 |

|

| 12" | 6" | 5" | Standard | 25 / Bundle |

As low as $20.85 |

|

| 12" | 6" | 8" | Standard | 25 / Bundle |

As low as $25.60 |

|

| 12" | 8" | 4" | Standard | 25 / Bundle |

As low as $25.60 |

|

| 12" | 8" | 6" | Standard | 25 / Bundle |

As low as $28.70 |

|

| 12" | 8" | 8" | Standard | 25 / Bundle |

As low as $23.95 |

|

| 12" | 9" | 5" | Standard | 25 / Bundle |

As low as $25.40 |

|

| 12" | 9" | 6" | Standard | 25 / Bundle |

As low as $26.45 |

|

| 12" | 9" | 8" | Standard | 25 / Bundle |

As low as $30.10 |

|

| 12" | 10" | 6" | Standard | 25 / Bundle |

As low as $28.35 |

|

| 12" | 10" | 8" | Standard | 25 / Bundle |

As low as $30.65 |

|

| 12" | 10" | 10" | Standard | 25 / Bundle |

As low as $30.95 |

|

| 12" | 12" | 9" | Standard | 25 / Bundle |

As low as $38.05 |

|

| 12 1/2" | 12 1/2" | 12" | Standard | 25 / Bundle |

As low as $46.35 |

|

| 13" | 10" | 5" | Standard | 25 / Bundle |

As low as $29.95 |

|

| 13" | 10" | 6" | Standard | 25 / Bundle |

As low as $31.30 |

|

| 13" | 10" | 10" | Standard | 25 / Bundle |

As low as $34.95 |

|

| 13" | 11" | 6" | Standard | 25 / Bundle |

As low as $32.75 |

|

| 13" | 11" | 11" | Standard | 25 / Bundle |

As low as $40.60 |

|

| 13" | 13" | 7" | Standard | 25 / Bundle |

As low as $39.55 |

|

| 13 1/2" | 13 1/2" | 7 1/2" | Standard | 25 / Bundle |

As low as $42.40 |

|

| 13" | 13" | 9" | Standard | 25 / Bundle |

As low as $42.55 |

|

| 13" | 13" | 10" | Standard | 25 / Bundle |

As low as $44.60 |

|

| 14" | 7" | 7" | Standard | 25 / Bundle |

As low as $27.15 |

|

| 14" | 8" | 6" | Standard | 25 / Bundle |

As low as $25.65 |

|

| 14 1/2" | 8 3/4" | 12" | Standard | 25 / Bundle |

As low as $36.00 |

|

| 14" | 10" | 6" | Standard | 25 / Bundle |

As low as $30.30 |

|

| 14" | 10" | 8" | Standard | 25 / Bundle |

As low as $30.65 |

|

| 14" | 10" | 10" | Standard | 25 / Bundle |

As low as $33.50 |

|

| 14" | 11" | 6" | Standard | 25 / Bundle |

As low as $33.10 |

|

| 14" | 12" | 6" | Standard | 25 / Bundle |

As low as $35.25 |

|

| 14" | 12" | 8" | Standard | 25 / Bundle |

As low as $37.65 |

|

| 14" | 14" | 7" | Standard | 25 / Bundle |

As low as $43.55 |

|

| 14" | 14" | 16" | Standard | 25 / Bundle |

As low as $59.80 |

|

| 15" | 9" | 8" | Standard | 25 / Bundle |

As low as $32.20 |

|

| 15" | 12" | 6" | Standard | 25 / Bundle |

As low as $39.15 |

|

| 15" | 12" | 10" | Standard | 25 / Bundle |

As low as $44.75 |

|

| 15" | 15" | 12" | Standard | 25 / Bundle |

As low as $59.55 |

|

| 16" | 8" | 8" | Standard | 25 / Bundle |

As low as $31.20 |

|

| 16" | 10" | 6" | Standard | 25 / Bundle |

As low as $31.25 |

|

| 16" | 10" | 8" | Standard | 25 / Bundle |

As low as $36.30 |

|

| 16" | 12" | 8" | Standard | 25 / Bundle |

As low as $39.70 |

|

| 16" | 12" | 10" | Standard | 25 / Bundle |

As low as $41.65 |

|

| 16" | 12" | 12" | Standard | 25 / Bundle |

As low as $45.25 |

|

| 16" | 13" | 10" | Standard | 25 / Bundle |

As low as $49.00 |

|

| 16" | 13" | 13" | Standard | 25 / Bundle |

As low as $55.40 |

|

| 16" | 14" | 12" | Standard | 25 / Bundle |

As low as $59.40 |

|

| 16" | 14" | 14" | Standard | 25 / Bundle |

As low as $59.40 |

|

| 16" | 16" | 8" | Standard | 25 / Bundle |

As low as $48.80 |

|

| 16" | 16" | 10" | Standard | 25 / Bundle |

As low as $52.30 |

|

| 16" | 16" | 12" | Standard | 25 / Bundle |

As low as $72.80 |

|

| 17 1/4" | 11 1/4" | 6" | Standard | 25 / Bundle |

As low as $36.30 |

|

| 17 1/4" | 11 1/4" | 8" | Standard | 25 / Bundle |

As low as $39.90 |

|

| 17" | 14" | 12" | Standard | 25 / Bundle |

As low as $56.65 |

|

| 17" | 14" | 14" | Standard | 25 / Bundle |

As low as $61.20 |

|

| 18" | 8" | 4" | Standard | 25 / Bundle |

As low as $30.95 |

|

| 18" | 10" | 6" | Standard | 25 / Bundle |

As low as $33.60 |

|

| 18" | 12" | 6" | Standard | 25 / Bundle |

As low as $39.20 |

|

| 18 1/2" | 12 1/2" | 7" | Standard | 25 / Bundle |

As low as $43.80 |

|

| 18" | 12" | 8" | Standard | 25 / Bundle |

As low as $42.85 |

|

| 18" | 12" | 9" | Standard | 25 / Bundle |

As low as $46.65 |

|

| 18" | 12" | 10" | Standard | 25 / Bundle |

As low as $44.90 |

|

| 18" | 12" | 12" | Standard | 25 / Bundle |

As low as $45.55 |

|

| 18" | 14" | 8" | Standard | 20 / Bundle |

As low as $38.50 |

|

| 18" | 14" | 12" | Standard | 25 / Bundle |

As low as $52.65 |

|

| 18" | 16" | 8" | Standard | 25 / Bundle |

As low as $63.95 |

|

| 18" | 16" | 14" | Standard | 25 / Bundle |

As low as $73.60 |

|

| 18" | 18" | 8" | Standard | 25 / Bundle |

As low as $57.15 |

|

| 18" | 18" | 10" | Standard | 20 / Bundle |

As low as $57.80 |

|

| 18" | 18" | 14" | Standard | 20 / Bundle |

As low as $60.85 |

|

| 18" | 18" | 16" | Standard | 20 / Bundle |

As low as $57.70 |

|

| 20" | 10" | 10" | Standard | 25 / Bundle |

As low as $46.05 |

|

| 20" | 16" | 8" | Standard | 25 / Bundle |

As low as $64.45 |

|

| 20" | 16" | 14" | Standard | 20 / Bundle |

As low as $56.20 |

|

| 20" | 16" | 16" | Standard | 15 / Bundle |

As low as $61.80 |

|

| 20" | 20" | 10" | Standard | 15 / Bundle |

As low as $58.60 |

|

| 20" | 20" | 12" | Standard | 15 / Bundle |

As low as $48.10 |

|

| 21" | 14" | 14" | Standard | 20 / Bundle |

As low as $57.30 |

|

| 22" | 12" | 10" | Standard | 20 / Bundle |

As low as $45.45 |

|

| 22" | 14" | 12" | Standard | 20 / Bundle |

As low as $46.85 |

|

| 22" | 14" | 14" | Standard | 20 / Bundle |

As low as $63.60 |

|

| 24" | 8" | 4" | Standard | 25 / Bundle |

As low as $48.80 |

|

| 24" | 12" | 10" | Standard | 25 / Bundle |

As low as $56.00 |

|

| 24" | 14" | 20" | Standard | 15 / Bundle |

As low as $60.15 |

|

| 24" | 16" | 8" | Standard | 20 / Bundle |

As low as $54.80 |

|

| 24" | 16" | 18" | Standard | 15 / Bundle |

As low as $58.85 |

|

| 24" | 18" | 18" | Standard | 10 / Bundle |

As low as $43.50 |

|

| 24" | 20" | 16" | Standard | 10 / Bundle |

As low as $45.60 |

|

| 24" | 24" | 12" | Standard | 10 / Bundle |

As low as $42.50 |

|

| 26" | 12" | 12" | Standard | 20 / Bundle |

As low as $55.20 |

|

| 26" | 18" | 10" | Standard | 15 / Bundle |

As low as $62.30 |

|

| 26" | 20" | 4" | Standard | 20 / Bundle |

As low as $52.20 |

|

| 26" | 20" | 16" | Standard | 10 / Bundle |

As low as $47.30 |

|

| 26" | 20" | 20" | Standard | 10 / Bundle |

As low as $53.80 |

|

| 26" | 26" | 36" | Standard | 5 / Bundle |

As low as $51.75 |

|

| 28" | 5" | 24" | Standard | 10 / Bundle |

As low as $49.00 |

|

| 28" | 10" | 10" | Standard | 25 / Bundle |

As low as $59.35 |

|

| 28" | 12" | 12" | Standard | 20 / Bundle |

As low as $56.65 |

|

| 28" | 16" | 10" | Standard | 20 / Bundle |

As low as $66.25 |

|

| 30" | 24" | 10" | Standard | 15 / Bundle |

As low as $96.10 |

|

| 30" | 24" | 12" | Standard | 15 / Bundle |

As low as $88.40 |

|

| 30" | 30" | 10" | Standard | 15 / Bundle |

As low as $109.95 |

|

| 30" | 30" | 12" | Standard | 10 / Bundle |

As low as $88.75 |

|

| 32" | 12" | 10" | Standard | 20 / Bundle |

As low as $56.70 |

|

| 32" | 18" | 8" | Standard | 15 / Bundle |

As low as $58.90 |

|

| 32" | 32" | 12" | Standard | 10 / Bundle |

As low as $112.20 |

|

| 36" | 8" | 4" | Standard | 25 / Bundle |

As low as $66.45 |

|

| 36" | 14" | 14" | Standard | 15 / Bundle |

As low as $91.15 |

|

| 36" | 16" | 16" | Standard | 15 / Bundle |

As low as $74.25 |

|

| 36" | 18" | 12" | Standard | 15 / Bundle |

As low as $71.85 |

|

| 36" | 36" | 12" | Standard | 10 / Bundle |

As low as $112.35 |

|

| 36" | 36" | 18" | Standard | 5 / Bundle |

As low as $63.75 |

|

| 40" | 18" | 8" | Standard | 10 / Bundle |

As low as $46.70 |

|

| 48" | 40" | 36" | Standard | 5 / Bundle |

As low as $101.10 |

|

Multi-depth cardboard boxes, also known as adjustable depth boxes or telescoping boxes, are a form of packing solution that provides size and depth flexibility. These boxes are made to fit things of various sizes by allowing you to alter the height or depth of the box to fit the contents snugly.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 6" | 6" | 4" | Multi-Depth | 25 / Bundle |

As low as $16.10 |

|

| 8" | 8" | 8" | Multi-Depth | 25 / Bundle |

As low as $24.60 |

|

| 8 1/2" | 8 1/2" | 8" | Multi-Depth | 25 / Bundle |

As low as $27.80 |

|

| 9" | 5" | 5" | Multi-Depth | 25 / Bundle |

As low as $18.80 |

|

| 9" | 9" | 9" | Multi-Depth | 25 / Bundle |

As low as $26.85 |

|

| 10" | 10" | 10" | Multi-Depth | 25 / Bundle |

As low as $33.05 |

|

| 11 1/4" | 8 3/4" | 12" | Multi-Depth | 25 / Bundle |

As low as $31.40 |

|

| 12" | 9" | 6" | Multi-Depth | 25 / Bundle |

As low as $30.95 |

|

| 12 1/4" | 9 1/4" | 12" | Multi-Depth | 25 / Bundle |

As low as $39.05 |

|

| 12 1/2" | 12 1/2" | 12" | Multi-Depth | 25 / Bundle |

As low as $52.45 |

|

| 12" | 12" | 18" | Multi-Depth | 25 / Bundle |

As low as $54.45 |

|

| 14" | 10" | 10" | Multi-Depth | 25 / Bundle |

As low as $41.90 |

|

| 14" | 12" | 12" | Multi-Depth | 25 / Bundle |

As low as $48.70 |

|

| 14" | 14" | 14" | Multi-Depth | 25 / Bundle |

As low as $61.10 |

|

| 17" | 17" | 17" | Multi-Depth | 25 / Bundle |

As low as $91.50 |

|

| 18" | 18" | 18" | Multi-Depth | 20 / Bundle |

As low as $79.40 |

|

| 24" | 24" | 24" | Multi-Depth | 10 / Bundle |

As low as $64.85 |

|

| 28" | 20" | 24" | Multi-Depth | 10 / Bundle |

As low as $92.90 |

|

11.25" x 8.75" x 12-10-8-6 " Multi-Depth Cardboard Boxes

Stock#: BX-110812MD

$

32

.70

/ Bundle of 25

12.25" x 9.25" x 12-10-8-6 " Multi-Depth Cardboard Boxes

Stock#: BX-120912MD

$

40

.65

/ Bundle of 25

12.5" x 12.5" x 12-10-8-6 " Multi-Depth Cardboard Boxes

Stock#: BX-121212-2MD

$

54

.65

/ Bundle of 25

12" x 12" x 18-16-14-12-10 " Multi-Depth Cardboard Boxes

Stock#: BX-121218MD

$

55

.30

/ Bundle of 25

Cube standard corrugated boxes are a corrugated box that has equal dimensions on all sides, making it a perfect cube shape. These boxes are commonly used for shipping and storing products that are smaller in size or need to be packed tightly together. They can be easily stacked and arranged in a storage space.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 4" | 4" | 4" | Cube | 25 / Bundle |

As low as $12.25 |

|

| 5" | 5" | 5" | Cube | 25 / Bundle |

As low as $15.70 |

|

| 6" | 6" | 6" | Cube | 25 / Bundle |

As low as $16.30 |

|

| 7" | 7" | 7" | Cube | 25 / Bundle |

As low as $20.80 |

|

| 8" | 8" | 8" | Cube | 25 / Bundle |

As low as $25.30 |

|

| 9" | 9" | 9" | Cube | 25 / Bundle |

As low as $25.60 |

|

| 10" | 10" | 10" | Cube | 25 / Bundle |

As low as $25.75 |

|

| 12" | 12" | 12" | Cube | 25 / Bundle |

As low as $34.20 |

|

| 14" | 14" | 14" | Cube | 25 / Bundle |

As low as $50.40 |

|

| 16" | 16" | 16" | Cube | 25 / Bundle |

As low as $61.75 |

|

| 17" | 17" | 17" | Cube | 25 / Bundle |

As low as $82.20 |

|

| 18" | 18" | 18" | Cube | 20 / Bundle |

As low as $60.55 |

|

| 20" | 20" | 20" | Cube | 10 / Bundle |

As low as $42.30 |

|

| 22" | 22" | 22" | Cube | 10 / Bundle |

As low as $47.20 |

|

| 24" | 24" | 24" | Cube | 10 / Bundle |

As low as $61.10 |

|

The white color of these boxes gives them a clean and professional appearance, making them ideal for shipping and storing products that require a higher level of presentation. They are commonly used in industries such as retail, e-commerce, and food and beverage.

| Stock # | Length | Width | Height | Qty/Bundle | Price |

|---|---|---|---|---|---|

| 4" | 4" | 4" | 25 / Bundle |

As low as $16.85 |

|

| 6" | 6" | 6" | 25 / Bundle |

As low as $20.30 |

|

| 8" | 8" | 8" | 25 / Bundle |

As low as $26.10 |

|

| 10" | 10" | 10" | 25 / Bundle |

As low as $34.35 |

|

| 12" | 9" | 4" | 25 / Bundle |

As low as $30.05 |

|

| 12" | 10" | 6" | 25 / Bundle |

As low as $34.05 |

|

| 12" | 12" | 6" | 25 / Bundle |

As low as $42.05 |

|

| 12" | 12" | 8" | 25 / Bundle |

As low as $50.90 |

|

| 12" | 12" | 12" | 25 / Bundle |

As low as $46.60 |

|

| 14" | 14" | 14" | 25 / Bundle |

As low as $70.00 |

|

| 16" | 16" | 16" | 25 / Bundle |

As low as $87.40 |

|

| 17 1/4" | 11 1/4" | 6" | 25 / Bundle |

As low as $38.65 |

|

| 17 1/4" | 11 1/4" | 8" | 25 / Bundle |

As low as $44.60 |

|

| 18" | 12" | 12" | 25 / Bundle |

As low as $61.05 |

|

| 24" | 12" | 12" | 25 / Bundle |

As low as $67.95 |

|

Shipping or storing long and narrow objects, such as golf clubs, banners, rolls of paper, fishing rods, curtain rods, and other elongated products, is an excellent use for these long cardboard boxes. The increased length of these containers helps provide protection and security for numerous products while they are being transported or stored.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 10" | 5" | 5" | Long | 25 / Bundle |

As low as $18.30 |

|

| 10" | 6" | 6" | Long | 25 / Bundle |

As low as $20.15 |

|

| 12" | 4" | 4" | Long | 25 / Bundle |

As low as $19.65 |

|

| 12" | 6" | 4" | Long | 25 / Bundle |

As low as $19.55 |

|

| 12" | 6" | 6" | Long | 25 / Bundle |

As low as $22.20 |

|

| 14" | 6" | 4" | Long | 25 / Bundle |

As low as $22.10 |

|

| 14" | 6" | 6" | Long | 25 / Bundle |

As low as $24.15 |

|

| 16" | 6" | 6" | Long | 25 / Bundle |

As low as $26.00 |

|

| 18" | 6" | 6" | Long | 25 / Bundle |

As low as $26.75 |

|

| 18" | 8" | 8" | Long | 25 / Bundle |

As low as $32.20 |

|

| 20" | 4" | 4" | Long | 25 / Bundle |

As low as $32.80 |

|

| 20" | 6" | 6" | Long | 25 / Bundle |

As low as $26.50 |

|

| 20" | 8" | 8" | Long | 25 / Bundle |

As low as $33.20 |

|

| 24" | 4" | 4" | Long | 25 / Bundle |

As low as $30.00 |

|

| 24" | 6" | 4" | Long | 25 / Bundle |

As low as $38.25 |

|

| 24" | 6" | 6" | Long | 25 / Bundle |

As low as $29.70 |

|

| 24" | 8" | 8" | Long | 25 / Bundle |

As low as $39.15 |

|

| 30" | 6" | 6" | Long | 25 / Bundle |

As low as $38.35 |

|

| 30" | 8" | 8" | Long | 25 / Bundle |

As low as $47.55 |

|

| 36" | 8" | 8" | Long | 25 / Bundle |

As low as $56.25 |

|

| 36" | 10" | 10" | Long | 20 / Bundle |

As low as $55.05 |

|

| 40" | 10" | 10" | Long | 15 / Bundle |

As low as $82.15 |

|

| 44" | 12" | 12" | Long | 15 / Bundle |

As low as $95.15 |

|

| 48" | 10" | 10" | Long | 20 / Bundle |

As low as $102.55 |

|

| 48" | 12" | 12" | Long | 10 / Bundle |

As low as $46.95 |

|

Side-loading cardboard boxes, also known as side-loading boxes or side-loading corrugated boxes, are a type of packaging that opens from the side as opposed to the top or bottom like conventional boxes. These containers have a one-of-a-kind design that enables them to be loaded and accessible from one of the longer sides of the container.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 24" | 5" | 18" | Side Load | 25 / Bundle |

As low as $60.30 |

|

| 36" | 5" | 24" | Side Load | 20 / Bundle |

As low as $96.60 |

|

| 36" | 5" | 36" | Side Load | 20 / Bundle |

As low as $109.55 |

|

Flat cardboard boxes with a short depth are particularly well-suited for packaging items that are vertically oriented or have a significant height compared to their width and depth. The unique design of these boxes makes them ideal for accommodating and protecting items that require upright storage and transportation.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 7" | 7" | 3" | Flat | 25 / Bundle |

As low as $17.40 |

|

| 8" | 8" | 2" | Flat | 25 / Bundle |

As low as $28.65 |

|

| 8" | 8" | 4" | Flat | 25 / Bundle |

As low as $23.75 |

|

| 10" | 7" | 3" | Flat | 25 / Bundle |

As low as $33.50 |

|

| 10" | 8" | 3" | Flat | 25 / Bundle |

As low as $21.15 |

|

| 10" | 8" | 4" | Flat | 25 / Bundle |

As low as $22.50 |

|

| 10" | 10" | 4" | Flat | 25 / Bundle |

As low as $23.80 |

|

| 11" | 11" | 3" | Flat | 25 / Bundle |

As low as $37.15 |

|

| 12" | 9" | 2" | Flat | 25 / Bundle |

As low as $29.95 |

|

| 12" | 9" | 3" | Flat | 25 / Bundle |

As low as $24.70 |

|

| 12" | 9" | 4" | Flat | 25 / Bundle |

As low as $25.75 |

|

| 12" | 10" | 3" | Flat | 25 / Bundle |

As low as $26.30 |

|

| 12" | 10" | 4" | Flat | 25 / Bundle |

As low as $26.45 |

|

| 12" | 12" | 2" | Flat | 25 / Bundle |

As low as $48.40 |

|

| 12" | 12" | 4" | Flat | 25 / Bundle |

As low as $29.95 |

|

| 12" | 12" | 6" | Flat | 25 / Bundle |

As low as $30.65 |

|

| 12 1/2" | 12 1/2" | 6" | Flat | 25 / Bundle |

As low as $35.65 |

|

| 13" | 10" | 4" | Flat | 25 / Bundle |

As low as $26.90 |

|

| 13" | 13" | 2" | Flat | 25 / Bundle |

As low as $54.30 |

|

| 13" | 13" | 3" | Flat | 25 / Bundle |

As low as $49.20 |

|

| 13" | 9" | 4" | Flat | 25 / Bundle |

As low as $40.80 |

|

| 14" | 8" | 4" | Flat | 25 / Bundle |

As low as $32.40 |

|

| 14" | 11" | 3" | Flat | 25 / Bundle |

As low as $31.15 |

|

| 14" | 12" | 4" | Flat | 25 / Bundle |

As low as $32.20 |

|

| 14" | 12" | 3" | Flat | 25 / Bundle |

As low as $48.80 |

|

| 14" | 14" | 2" | Flat | 25 / Bundle |

As low as $60.65 |

|

| 14" | 14" | 4" | Flat | 25 / Bundle |

As low as $38.95 |

|

| 15" | 10" | 4" | Flat | 25 / Bundle |

As low as $28.55 |

|

| 15" | 12" | 5" | Flat | 25 / Bundle |

As low as $54.50 |

|

| 15" | 15" | 3" | Flat | 25 / Bundle |

As low as $54.15 |

|

| 15" | 15" | 4" | Flat | 25 / Bundle |

As low as $40.70 |

|

| 15" | 15" | 5" | Flat | 25 / Bundle |

As low as $46.25 |

|

| 16" | 8" | 4" | Flat | 25 / Bundle |

As low as $32.45 |

|

| 16" | 12" | 4" | Flat | 25 / Bundle |

As low as $33.60 |

|

| 16" | 12" | 6" | Flat | 25 / Bundle |

As low as $40.70 |

|

| 16" | 14" | 6" | Flat | 25 / Bundle |

As low as $45.85 |

|

| 16" | 16" | 4" | Flat | 25 / Bundle |

As low as $48.70 |

|

| 17" | 14" | 5" | Flat | 25 / Bundle |

As low as $43.60 |

|

| 17" | 17" | 4" | Flat | 25 / Bundle |

As low as $53.40 |

|

| 17" | 17" | 6" | Flat | 20 / Bundle |

As low as $45.65 |

|

| 18" | 10" | 4" | Flat | 25 / Bundle |

As low as $32.20 |

|

| 18" | 12" | 3" | Flat | 25 / Bundle |

As low as $63.05 |

|

| 18" | 12" | 4" | Flat | 25 / Bundle |

As low as $37.20 |

|

| 18" | 14" | 4" | Flat | 25 / Bundle |

As low as $43.20 |

|

| 18" | 16" | 6" | Flat | 25 / Bundle |

As low as $54.10 |

|

| 18" | 18" | 4" | Flat | 25 / Bundle |

As low as $56.90 |

|

| 19" | 12" | 4" | Flat | 25 / Bundle |

As low as $40.25 |

|

| 20" | 10" | 4" | Flat | 25 / Bundle |

As low as $32.95 |

|

| 20" | 10" | 6" | Flat | 25 / Bundle |

As low as $35.30 |

|

| 20" | 12" | 4" | Flat | 25 / Bundle |

As low as $42.00 |

|

| 20" | 12" | 6" | Flat | 25 / Bundle |

As low as $43.15 |

|

| 20" | 14" | 3" | Flat | 25 / Bundle |

As low as $56.40 |

|

| 20" | 14" | 4" | Flat | 25 / Bundle |

As low as $45.50 |

|

| 20" | 14" | 6" | Flat | 25 / Bundle |

As low as $49.15 |

|

| 20" | 15" | 6" | Flat | 25 / Bundle |

As low as $57.85 |

|

| 20" | 16" | 6" | Flat | 25 / Bundle |

As low as $56.90 |

|

| 20" | 18" | 4" | Flat | 25 / Bundle |

As low as $80.75 |

|

| 20" | 20" | 2" | Flat | 20 / Bundle |

As low as $89.95 |

|

| 22" | 10" | 6" | Flat | 25 / Bundle |

As low as $38.90 |

|

| 24" | 10" | 4" | Flat | 25 / Bundle |

As low as $37.20 |

|

| 24" | 12" | 4" | Flat | 25 / Bundle |

As low as $42.80 |

|

| 24" | 14" | 4" | Flat | 25 / Bundle |

As low as $50.05 |

|

| 24" | 14" | 6" | Flat | 25 / Bundle |

As low as $56.20 |

|

| 24" | 16" | 4" | Flat | 25 / Bundle |

As low as $63.90 |

|

| 24" | 18" | 4" | Flat | 20 / Bundle |

As low as $50.10 |

|

| 24" | 24" | 9" | Flat | 10 / Bundle |

As low as $45.55 |

|

| 26" | 15" | 5" | Flat | 20 / Bundle |

As low as $52.55 |

|

| 26" | 20" | 6" | Flat | 20 / Bundle |

As low as $88.15 |

|

| 28" | 12" | 6" | Flat | 25 / Bundle |

As low as $53.60 |

|

| 28" | 16" | 7" | Flat | 20 / Bundle |

As low as $61.30 |

|

| 36" | 12" | 6" | Flat | 20 / Bundle |

As low as $79.25 |

|

| 36" | 18" | 6" | Flat | 15 / Bundle |

As low as $94.40 |

|

When you need to package or ship things that are vertically oriented and have a large height in comparison to their width and depth, tall cardboard boxes are an ideal alternative because they give you more height for your money. Items that need to be stored or transported upright in an upright position will benefit from these boxes because they are specially designed to provide a safe and sturdy packaging option for the item.

| Stock # | Length | Width | Height | Box Type | Qty/Bundle | Price |

|---|---|---|---|---|---|---|

| 4" | 4" | 8" | Tall | 25 / Bundle |

As low as $17.95 |

|

| 4" | 4" | 12" | Tall | 25 / Bundle |

As low as $24.30 |

|

| 4" | 4" | 20" | Tall | 25 / Bundle |

As low as $32.05 |

|

| 4" | 4" | 24" | Tall | 25 / Bundle |

As low as $36.50 |

|

| 4" | 4" | 28" | Tall | 25 / Bundle |

As low as $39.15 |

|

| 4" | 4" | 30" | Tall | 25 / Bundle |

As low as $42.30 |

|

| 4" | 4" | 36" | Tall | 25 / Bundle |

As low as $44.30 |

|

| 4" | 4" | 48" | Tall | 25 / Bundle |

As low as $57.85 |

|

| 4" | 4" | 60" | Tall | 25 / Bundle |

As low as $75.40 |

|

| 4" | 4" | 72" | Tall | 15 / Bundle |

As low as $54.75 |

|

| 6" | 6" | 10" | Tall | 25 / Bundle |

As low as $21.60 |

|

| 6" | 6" | 12" | Tall | 25 / Bundle |

As low as $23.65 |

|

| 6" | 6" | 14" | Tall | 25 / Bundle |

As low as $34.90 |

|

| 6" | 6" | 18" | Tall | 25 / Bundle |

As low as $37.40 |

|

| 6" | 6" | 30" | Tall | 25 / Bundle |

As low as $55.30 |

|

| 6" | 6" | 36" | Tall | 25 / Bundle |

As low as $54.10 |

|

| 6" | 6" | 48" | Tall | 25 / Bundle |

As low as $72.60 |

|

| 7" | 7" | 12" | Tall | 25 / Bundle |

As low as $26.60 |

|

| 8" | 8" | 14" | Tall | 25 / Bundle |

As low as $30.60 |

|

| 8" | 8" | 16" | Tall | 25 / Bundle |

As low as $32.55 |

|

| 8" | 8" | 17" | Tall | 25 / Bundle |

As low as $32.95 |

|

| 8" | 8" | 20" | Tall | 25 / Bundle |

As low as $36.75 |

|

| 8" | 8" | 30" | Tall | 25 / Bundle |

As low as $46.55 |

|

| 8" | 8" | 40" | Tall | 20 / Bundle |

As low as $54.45 |

|

| 8" | 8" | 42" | Tall | 20 / Bundle |

As low as $81.20 |

|

| 8" | 8" | 60" | Tall | 15 / Bundle |

As low as $80.35 |

|

| 10" | 10" | 24" | Tall | 25 / Bundle |

As low as $49.65 |

|

| 10" | 10" | 30" | Tall | 25 / Bundle |

As low as $77.30 |

|

| 10" | 10" | 38" | Tall | 25 / Bundle |

As low as $75.35 |

|

| 10" | 10" | 40" | Tall | 25 / Bundle |

As low as $72.00 |

|

| 10" | 10" | 60" | Tall | 15 / Bundle |

As low as $107.65 |

|

| 12" | 12" | 48" | Tall | 15 / Bundle |

As low as $87.85 |

|

| 12" | 12" | 60" | Tall | 10 / Bundle |

As low as $85.30 |

|

| 15" | 15" | 36" | Tall | 15 / Bundle |

As low as $89.35 |

|

No results found, please check your filters!

Clear Filters

Link copied

See Results

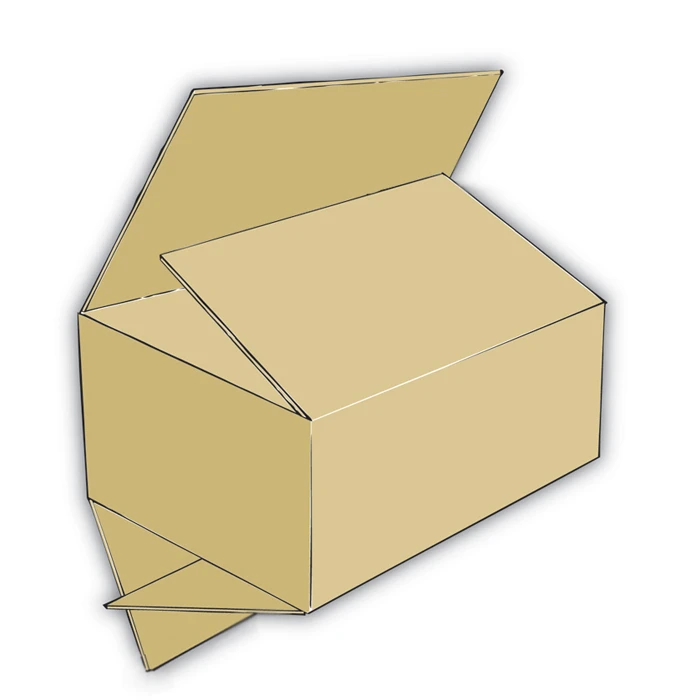

RSC (Regular Slotted Container) are the typical everyday Corrugated boxes. The lengthwise flaps are one-half the container's width so they meet in the center when folded. The RSC box can be used for most products and is the most common box style.

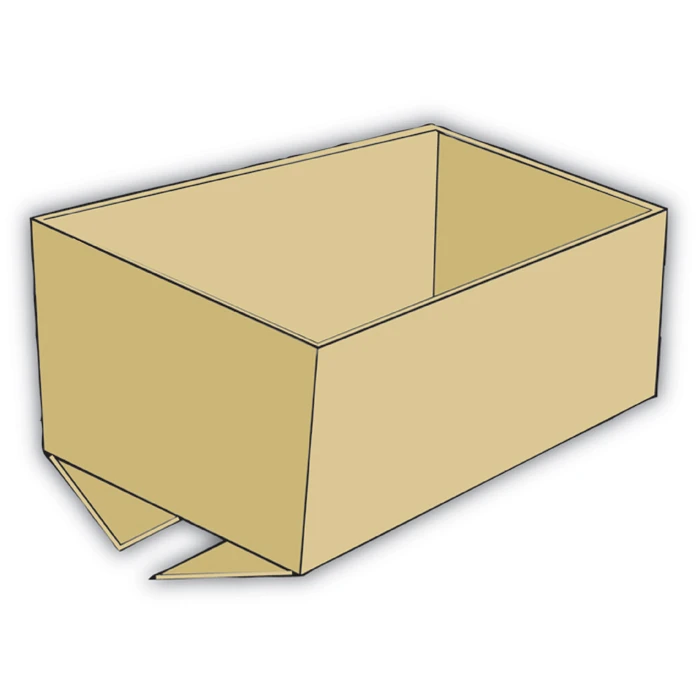

These boxes only have closing flaps on one open end of the box. These are for applications in which you would overload the box with goods or implement another top enclosure.

FOL (Full Overlap Slotted Containers) boxes have lengthwise flaps that are almost the width of the box. When these flaps are closed, the outer flaps come to within one inch of making a complete overlap. This style of box is especially resistant to rough handling. HD (Heavy Duty) and DW (Double-Wall) boxes provide even tougher choices.

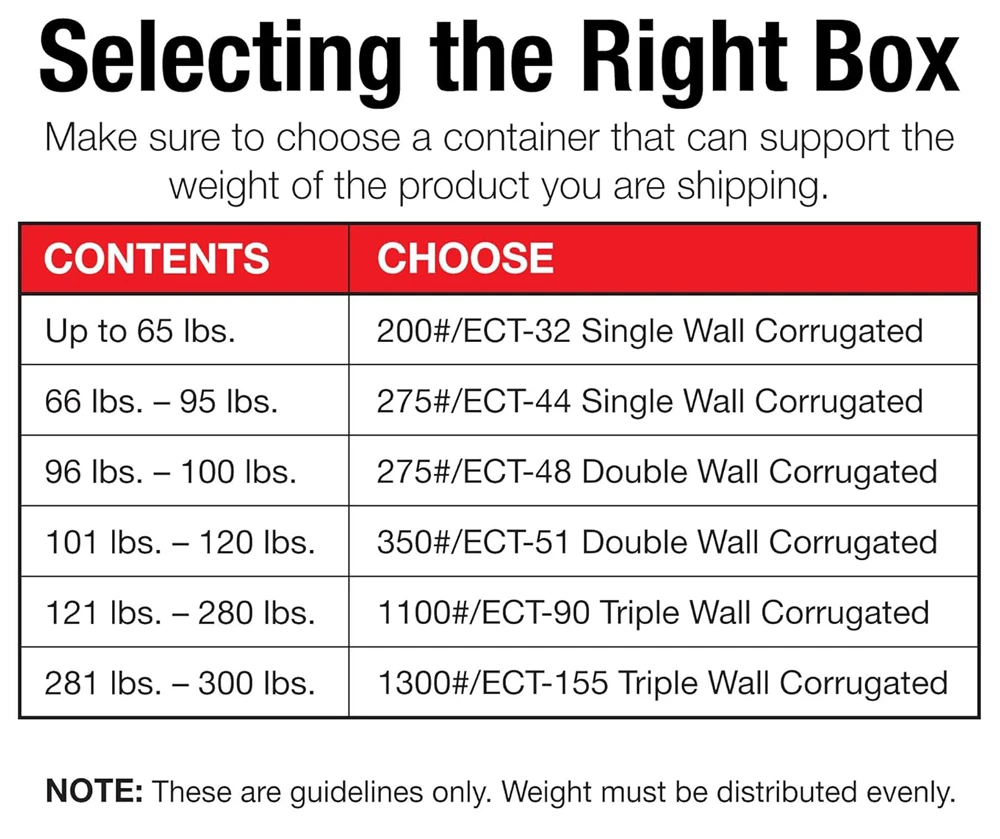

What Is The Difference Between 32 ECT, 200 Lb. Test, and 275 Lb. Test Boxes?

Choosing the right cardboard box for shipping or packaging will help your contents survive the perils of everyday handling.

Eliminate shipping damages and costly returns by choosing the right box for your application.

Still unsure of what to use? Call (800) 820-4722 to speak to one of our packaging experts. They are standing by to answer your questions and help you choose the right corrugated cardboard box for your packaging requirements.

Comparing Bursting Test vs. Edge Crush Test

There are currently two tests used throughout the corrugated industry to determine strength.

1. Bursting (Mullen) Test = A measure of the force required to rupture or puncture the face of corrugated board and is measured by a Mullen Tester.

2. Edge Crush Test (ECT) = ECT is a measure of the edgewise compressive strength of the corrugated board. It is measured by compressing a small segment of the board on edge between two rigid platens or plates perpendicular to the direction of the flutes until a peak load is established. This is measured in pounds per lineal inch of load-bearing edge (lb/in) but usually reported as an ECT value (for example, 44 ECT). Information from https://statweb.stanford.edu

| Box Type | Bursting Test | Minimum Edge Crush Test | Maximum Load Per Carton |

| Standard | 200# | 32 ECT | 40 lbs. |

| Heavy Duty | 275# | 44 ECT | 65 lbs. |

| Heavy Duty - Double Wall | 275# | 48 ECT | 80 lbs. |