to select

to navigate

esc to close

Popular Pages

Go Back

Custom Packaging

Bags & Liners

Tubing & Film

Packaging Supplies

Shop by Application

Hi there,

how can we help you today?

Shipping options will change based on location.

Current ZIP Code:

Update zip code

User my current location

Order before 4pm EST for same-day shipping on in-stock items!

Lowest Price Guarantee

30-Day Returns & Exchanges

100% Satisfaction Guarantee

$37.65 / Case of 100

Ship to ZIP Code

| Save up to 30.6% when you order in bulk | |||||

|---|---|---|---|---|---|

| Quantity | Pieces | Per Case | Total | You Save | |

| 1 Case | 100 | $37.65 | $37.65 | 16.7% | |

| 3 Cases | 300 | $34.20 | $102.60 | 24.3% | |

| 6 Cases | 600 | $31.35 | $188.10 | 30.6% | |

| 6+ Cases | 600+ | Get a free high quantity quote | |||

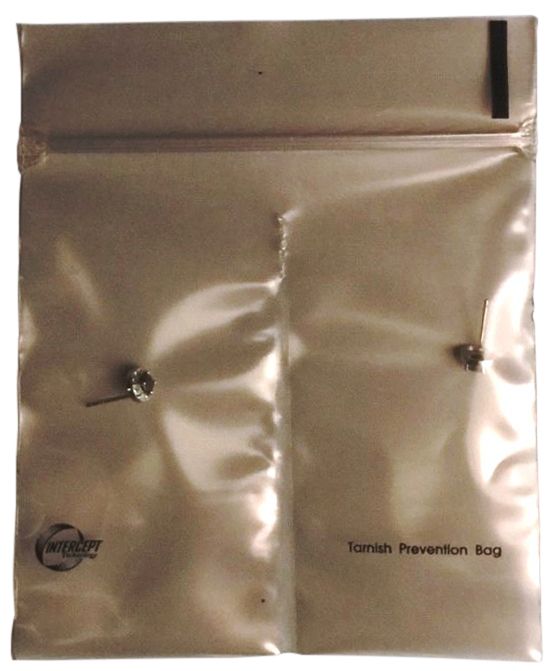

4 x 4 Anti Tarnish Zip Lock Jewelry Bags with a divided compartment provide clean, non-abrasive, non-toxic, environmentally friendly tarnish prevention. 3 mil Anti-Tarnish Compartment Jewelry Bags keep your silver jewelry, flatware and other precious silver metals protected to maintain shine, brilliance and luster for up to 3 years.

BenefitsNo customer reviews