Recently Viewed

to select

to navigate

esc to close

Popular Pages

Recently Viewed

Go Back

Custom Packaging

Bags & Liners

Tubing & Film

Packaging Supplies

Shop by Application

Hi there,

how can we help you today?

Shipping options will change based on location.

Current ZIP Code:

Update zip code

User my current location

Order before 4pm EST for same-day shipping on in-stock items!

Lowest Price Guarantee

30-Day Returns & Exchanges

100% Satisfaction Guarantee

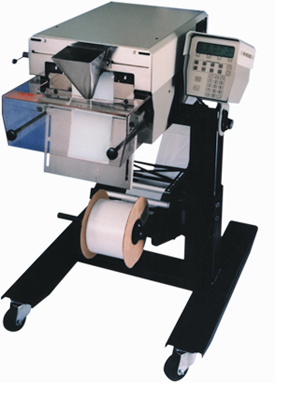

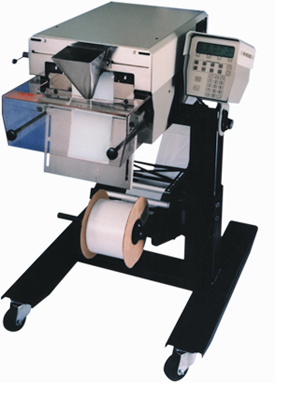

Pre-opened bags are open on one side for easy product insertion and perforated on

the back for easy tear-off. Ideal for high-volume packaging operations. Compatible

with most automated bagging machines like AUTOBAG, Sharp, Titan, and Advance Poly.

Linear low-density Metallocene also ensures better heat seals when used with our

semiautomated bagging machines.

Pre-opened bags are open on one side for easy product insertion and perforated on

the back for easy tear-off. Ideal for high-volume packaging operations. Compatible

with most automated bagging machines like AUTOBAG, Sharp, Titan, and Advance Poly.

Linear low-density Metallocene also ensures better heat seals when used with our

semiautomated bagging machines.

Auto bags are a type of plastic bag that is designed to be used with an automated bagging machine. They are typically manufactured on a roll and feature a perforated line between each bag, which enables the bagging machine to automatically dispense and fill the bags as needed. Auto bags are often used in high-volume packaging applications and can be made from a variety of plastic materials, including polyethylene, polypropylene, and co-extruded films.

Pre-opened bags, on the other hand, are plastic bags that are pre-opened and stacked for easy dispensing. They do not have perforations between each bag and are typically loaded into a bagging machine manually. Pre-opened bags are often used in applications where a bagging machine is not necessary, or where smaller quantities of bags are required.

One key difference between auto bags and pre-opened bags is their method of dispensing. Auto bags are designed to be used with an automated bagging machine and are dispensed one at a time as needed, while pre-opened bags are dispensed manually or in small quantities. Additionally, auto bags are manufactured on a roll with perforations, while pre-opened bags are typically stacked and bundled.

Overall, both auto bags and pre-opened bags are useful plastic bag solutions for a variety of packaging applications, but their intended use and method of dispensing can vary. It's important to consider the specific needs of your application when choosing between these two options.

What machines are auto bags compatible with?

These bags are suitable for use with a wide range of automatic bagging devices, such as Autobag Baggers and Rollbag Baggers.

How are autobags on rolls beneficial in production line operations?

They contribute to the efficiency of manufacturing lines by maintaining a steady production rate, which enables packers to concentrate on filling while reducing lag times.

What are auto bags and how are they most often used?

Auto bags on rolls for automatic bagging machines are a specific kind of packaging solution that may be used with automatic bagging machines. Each bag can include a perforation that allows it to be separated easily and has an open side to insert items into it quickly. They are utilized to optimize production lines by providing a uniform packaging pace, and they are commonly employed in industries such as industrial manufacturing, food service, retail packaging, and medical supplies. Their primary function is to protect products from being lost, misplaced, or damaged throughout the packaging process. In the packing process, auto bags on rolls enable efficiency, which is particularly beneficial for high-volume operations.